PEUGEOT HDI TIMING BELT INSTALLATION

Peugeot hdi 206 1.4 HDi 8HX/8HZ

The timing belt system may look a little

tricky to change, but with a little know-how

and the appropriate tools, it will prove to be

an ideal repair for an independent garage.

The engine has been identified as an

interference type, so in the event of the timing

belt failing, chance of engine damage is

extremely high. It is important to install a new

timing belt system on an engine while it is at

ambient room temperature. Always adhere to

turning the engine in the normal direction of

rotation unless advised otherwise by the OEM

installation instructions. Recommended torque

values should always be used. It is

recommended that all the tensioners, idlers

and fixings are replaced as advised by the

manufacturer during the timing belt

replacement.

A two post ramp is ideal for carrying out

timing belt replacements, it is also vital that

the appropriate timing belt replacement tools

are available and used, and these are readily

available from most motor factors. If the

vehicle is equipped with alloy wheels, it’s a

good idea to locate the adaptor key before

you start.

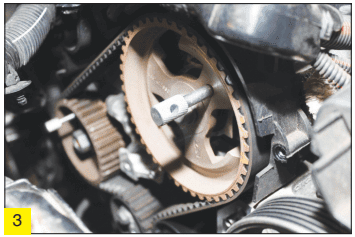

Once the vehicle is on the ramp, for

safety reasons and best practice, we

disconnected the negative battery lead.

Remove the O/S/F wheel and wheel arch

liner; this gives access to a plastic shield which

can then be removed. The auxiliary drive belt is

now fully visible and accessible (fig 1), make a

note of routing if required, rotate the auxiliary

belt tensioner clockwise to the released

position, lock with a pin, remove the auxiliary

belt and check for wear and deterioration.

Replacement is advised during timing belt

replacement.

This vehicle was also fitted with an Over

Running Alternator Pulley (OAP) which should

also be tested for correct operation and

replaced if necessary. At this point, unclip the

wiring harness from the lower timing belt

cover that goes to the crank sensor and detach

from the crank sensor and remove the auxiliary

belt tensioner.

Lower the vehicle close to ground level,

unclip the wiring and fuel pipes from the top

timing belt cover, support the engine either by

means of an engine brace or engine support

beam, remove the engine control unit from

the engine bay, remove the engine mount

cover, rubber bump stop and the engine

mount. Undo the five bolts in the top timing

belt cover and remove.

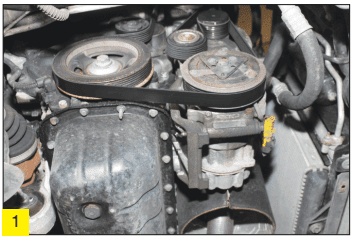

Raise the vehicle, insert the crank locking

pin from the back of the engine through and

into the back of the flywheel (this is a locking

device not a timing location), located in a

central position (fig 2). Undo the centre bolt

on the crankshaft pulley and remove pulley

and locking pin, remove the crankshaft

position sensor and shield. Undo the five lower

timing belt cover bolts and remove the cover.

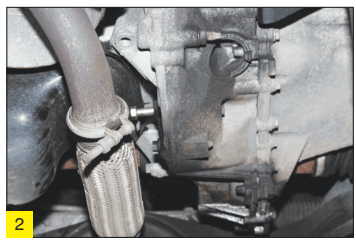

Refit crankshaft pulley bolt and rotate engine

until crank, cam and fuel pump locations align.

Lock crank, cam and fuel pump with pins (figs

3 and 4), slacken the tensioner and remove,

and then remove the timing belt.

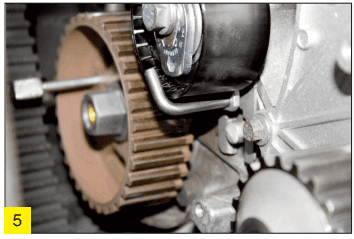

Carry out a thorough inspection of the

timing belt area including pulleys and water

pump. Replace the timing belt tensioner,

making sure it is located correctly (fig 5), idler

and fixings supplied. Replace the tensioner

bolt, the idler and stud. Fit the new timing belt

in the following order, crankshaft, idler,

camshaft, water pump, fuel pump and then

the tensioner. Tension the belt by aligning the

marks on the tensioner and torque bolt. As per

instructions, rotate the engine ten revolutions

and recheck timing and tension, (when we

carried this out the fuel pump locking pin did

not line up, after two more rotations it all

aligned and locked with the pins).

Refit all components, reconnect battery

lead and remember to reset the clock, radio

code, electric windows and remote locking.

Run the engine to ensure all is correct.

Malcolm Short, Schaeffler

Timing belt replacement is due every 140-160,000 miles, or 10 years whatever comes first, depending on date of manufacture, but always check the manufactures recommendations. INA takes a closer look at this popular model.